Pad printing

What is pad printing?

Pad printing is an indirect engraving process. It is a very flexible printing technique with wide-ranging possibilities. Pad printing allows you to print your logo not only on smooth surfaces, but also curved, round and uneven ones. It is classified as flat printing, making it very similar to screen printing to a certain degree.

Pad printing: How it works

In the pad printing process, the print motif or logo is etched, lasered or washed out as a kind of indentation in a plate, which is called the cliché. This whole/pattern in the cliché is then filled with ink. Excess paint is scraped off with a squeegee, something similar to a knife, and disposed of.

The only paint that remains is the paint of the actual pattern, so the artwork can be transferred correctly. A stamp made of silicone or rubber, also known as a pad, is pressed into the indentation and absorbs the existing colour. This pad, or stamp, is very elastic and can adapt to any shape. The pad is then pressed onto the promotional item and thus transfers the absorbed colour to the printing surface.

Other things to consider

As there is a size limit for the printing stamps, the design is also limited in terms of its format. Before an advertising medium is commissioned, it is best to find out what the maximum size a print shop offers in pad printing. If necessary, another printing technique must be used if the desired motif is too large.

Furthermore, the printing stamp is also limited in terms of ink absorption. Since it can only absorb a certain amount of paint, it is possible that when backgrounds are too dark, the darkness can show through the light colour layers of the print motif. Some materials also require special pre-treatment, without which printing would not work. These include polyphons, for example, such as those found in plastics and used in the production of toys, household goods or packaging.

Advantages and benefits

- Versatile: The highly elastic nature of the pad means it can be printed on almost any promotional item, regardless of the material, shape and surface texture.

- Affordable: Pad printing is a cheap printing process, regardless if you are printing large or small quantities.

- Colour variety: The company logo and advertising message can be applied to the advertising medium in up to four colours.

- High-quality: Choose between different types of colours that have an impact on the durability and robustness of the print.

- Speedy: Pad printing is a fast finishing process that can be used to print large quantities of promotional items in a very short time. This is ideal for many 48 hour products.

- Environmentally friendly: Pad printing is more sustainable than other printing methods. The elastic pad can be cleaned and reused after the printing process, which makes pad printing a sustainable and an eco-friendly printing process.

Pad printing vs. screen printing

In contrast to pad printing, screen printing is not suitable for tiny and fine prints. Additionally, screen printing can only be applied on smooth and flat surfaces, such as branded tote bags, branded t-shirts or umbrellas.

Pad printing: colour options

With pad printing, both single and multicolour prints are possible. When choosing your design, you can decide whether you want to have your promotional product printed with just one colour or several ones.

- One-component paint: It is characterized by high resistance to abrasion and easy processing. The latter makes them very attractive to advertisers, since editing promotional items with this colour is very inexpensive.

- Two-component ink: If the advertising medium to be printed is subject to heavy use and is long-lasting, we recommend using this printing ink because of its special composition.

- Mixed colours: If you have a very specific colour shade in mind, for example that of the corporate identity or brand, you can reproduce it in detail with the mixed colours.

- UV Inks: These are very expensive and require great caution and care in processing. Since the moisture in the paint evaporates quickly, they are resistant to solvents.

- LED colours: LED colours are more environmentally friendly and easier to work with than UV ones. In addition, they are cheaper and more energy-efficient in the printing process. They have all the positive properties of their UV predecessors and also boast quick drying and innovation.

Paying attention to the correct file format and the colour space of the desired artwork is just as important as the question of what type of colour you want to use for printing your promotional item. Most printers work with the CMYK model, which is why it is recommended to design and create your logo in this scheme, otherwise unwanted deviations in the colour tone can occur.

Commonly asked questions

Is pad printing expensive?

Three major factors determine the price when choosing pad printing: set-up costs, number of colours and the type of promotional item to be printed. Firstly, the set-up costs depend on the artwork to be printed and its size, since a cliché must be created for the template at the beginning.

Secondly, the price depends on how many colours are to be printed and how many promotional gifts are to be printed. An item with a one-colour print is significantly cheaper than an item with a multicolour design. The type of promotional item in question, i.e. its surface structure and quality, form the third cost factor.

Last but not least, pad printing is actually one of the most affordable printing techniques for promotional merchandise.

Is special production on a promotional product possible?

Yes, most printers can easily implement complex and customer-specific special requests. If you ever have the feeling there isn't the right item for you because you have something very special and unique in mind, then don't hesitate and simply let us know your wishes and ideas. The advertising experts give competent advice so that your advertising campaign can be a complete success.

Which promotional gifts work best with pad printing?

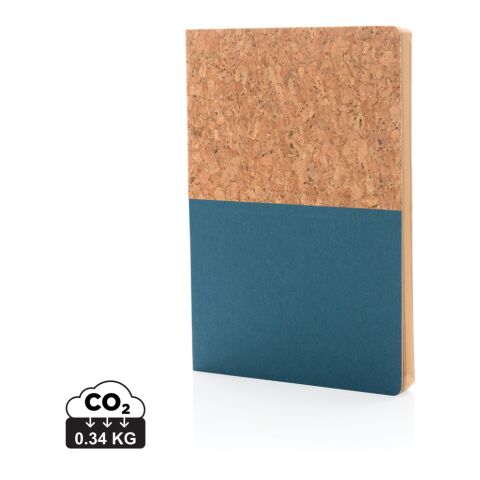

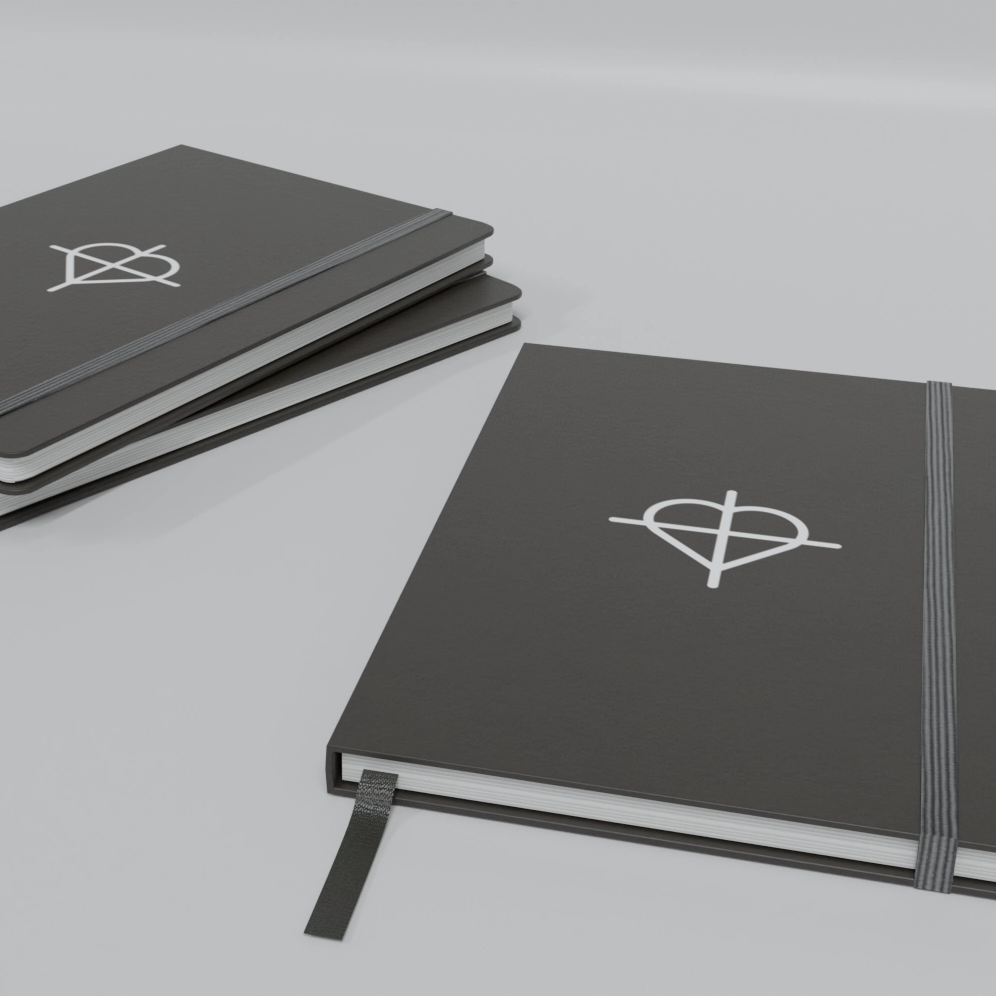

Due to the variety of printing that is possible with this printing process, this type of printing can be used for numerous advertising products to reach potential customers. Due to the high flexibility of the pad, it can be applied to almost any surface. A curved, round and uneven surface can also be easily printed, as the pad is flexible enough to adapt to the shape of the promotional item. The material properties barely set any limits to the printing process which enables the printing of soft and hard materials such as plastic, wood, glass, metal or porcelain.

It is therefore not surprising that almost all promotional items can be nicely printed with the help of pad printing and printed with a logo or slogan. Items that are outwardly curved, such as promotional pens and branded water bottles, or items that are curved inwards, such as branded cups and mugs, are no problem. Also, round promo items such as ornaments, stress balls can be easily refined. Printing on classic promotional items with smooth surfaces such as USB products, power banks and lighters is not uncommon either, not to mention textile and paper products. Almost every conceivable advertising product can be provided with your own brand advertising message using pad printing.

Do you still have questions about pad printing?

We hope that we were able to answer all your questions about the pad printing process. If you have any more questions, simply contact us, and we can answer anything else you wish to know. Our promotional products professionals can assist you.

.png)

.png)

.png)