Transfer printing

What is transfer printing?

Transfer printing, also called textile printing, is an indirect printing process and, although it may not look like it, it's under the umbrella of screen printing. The difference between transfer and screen printing is that with transfer printing, the artwork is not printed directly on the promotional item, but only on a special foil, also known as transfer paper.

Anyone who has perhaps already tried iron-on printing at home, in which the photo are ironed onto textiles using iron-on transfers, will find transfer printing familiar. This form of printing is mostly used for textiles, such as sweaters, shirts, jackets and so much more. However, other materials such as metals, plastics and ceramics can also be printed using this technique.

How does transfer printing work?

In this process, the artwork is either punched out of the transfer paper and cut to fit, or printed on a white transfer film, also punched out and cut to size, and then applied to the fabric to be printed with a transfer press. It is particularly important that constant pressure and constant heat are applied, otherwise the artwork would come loose or peel off after a while.

The back of the transfer papers is coated with a sticky substance that ensures the design adheres to textiles and other materials and, when transferred correctly, ensures long-lasting quality and durability. As long as the film has not yet been applied to the material to be printed. This sticky side is covered with a protective film so that the adhesive cannot wear off beforehand.

In addition to normal transfer printing, there is also the special form of digital transfer. Both forms of printing do not differ greatly from each other, but the digital form offers an unlimited variety of colours, whereas the normal transfer print is limited to a maximum of five. The colour is printed on a very special transfer paper using a digital printer and applied to the material to be printed using the transfer press. However, with this variant, the printed artwork clearly loses quality during the washing process, since the film crumples and the colour becomes paler.

The advantages of transfer printing

- Due to the different transfer foils, many colour combinations and effects are possible.

- A logo applied by transfer printing impresses with its high resistance to washing and usage.

- Digital printing enables an unlimited number of colours to perfectly implement your wishes.

- Transfer printing is a high-quality finishing technique for placing an advertising message with a target group.

The disadvantages of transfer printing

- Transfer printing produces large amounts of paper waste. Thus, transfer printing is not environmentally friendly.

- In contrast to screen printing and digital printing, the transfer printing process is significantly more time-consuming and expensive.

Commonly asked questions

Here are a few of the answers to the most frequently asked questions:

What colour options are there for transfer printing?

This type of printing allows the image to be printed to be displayed in up to five colours. This and the magnificent depth of colour with its high opacity offer numerous possibilities to realize the ideas and imaginations exactly as it is intended. Whether glittering, reflective or velvety soft, transfer printing realizes all kinds of projects. With digital printing, an unlimited number can even be accessed, which can be particularly useful if very specific colour gradients or a colour combination from, for example, corporate identity, has to be made.

Is transfer printing expensive?

Unlike screen printing, for example, transfer printing is significantly more expensive. On the one hand, it depends very much on the number of colours to be used. Of course, the more of them that have to be printed, the higher the final price increases. On the other hand, this type of printing is very complex, as it often involves a lot of manual work. Finally, the punched-out artworks have to be cut out precisely by hand so that the edges are clear and sharp. The number of pieces, the size of the artwork and the object to be printed, such as a watch or textile objects, also play a major role.

What are transfer papers?

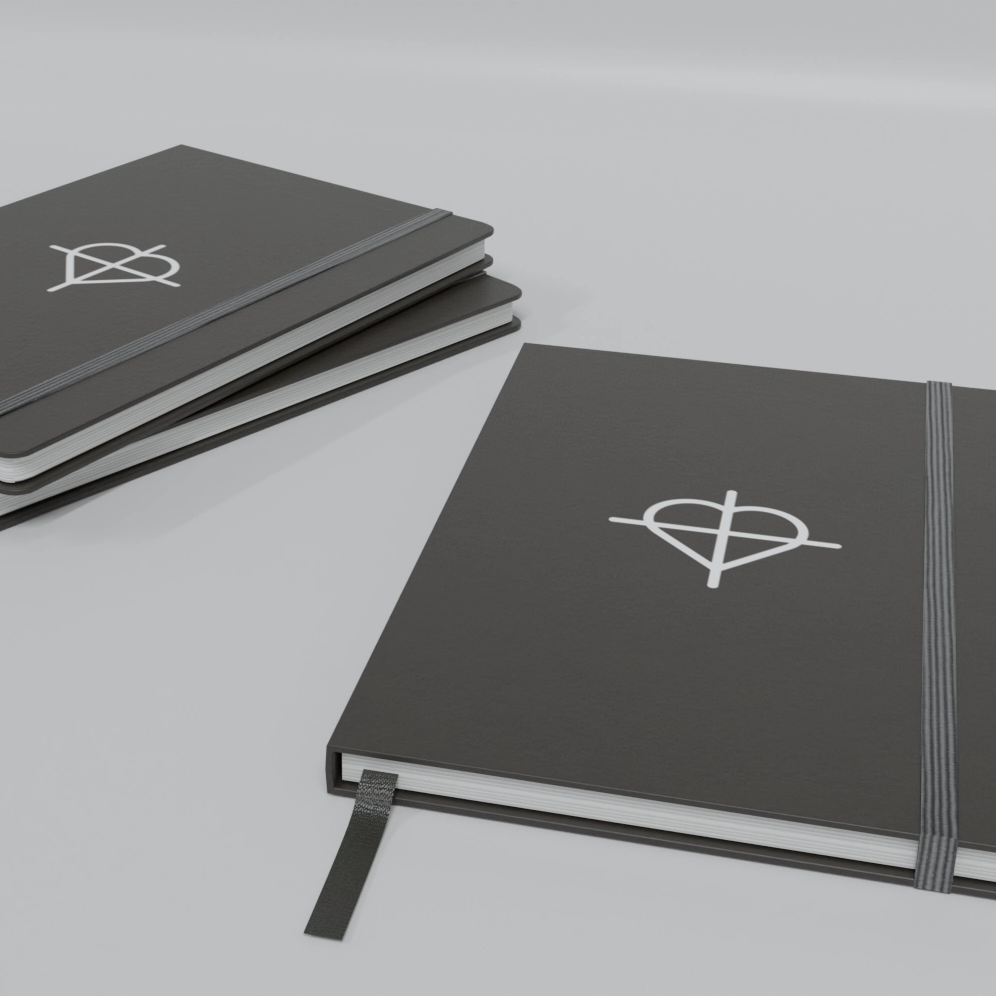

In order to present an advertising message or artwork perfectly, there are many different transfer papers to choose from. In addition to the white paper, which can be printed with a company logo, claim, emblem or a completely different embellishment, there are also specially processed papers that can come up with "special effects". If the image to be printed should not only look good, but also feel good, velvety transfer paper can be just the thing.

In addition to the interesting look, the printed article stands out due to its warm feel and creates positive associations and sympathy for the advertising company. But a brilliant appearance is also easily possible by having the promotional item printed with reflective transfer paper. If the printed article should look very eye-catching, there are even glittered foils in all shades. In general, transfer foils are characterized by their impressive robustness and longevity in the face of sunlight or environmental influences such as high humidity, rain or snow. This makes textile printing extremely attractive, especially for textiles such as backpacks, jackets, cotton bags or umbrellas.

What promotional products can be branded through transfer print?

As already mentioned, the transfer printing process is best suited for textile advertising material. Regardless of whether it is branded shirts, branded bags, caps, jackets or special work clothing such as aprons and waistcoats, with high-quality textile finishing such as transfer printing, the advertising company always remains positive in people's minds. And no matter how often the promotional item is thrown in the washing machine, the company logo or artwork always stays in place thanks to the high wash resistance of the transfer paper.

But other fabrics can also be finished with this printing process. Ceramic products, such as cups and mugs, look much better with a chic logo and give customers and employees a good start to the day. But not only at home, but also on the go, articles printed with textile printing can always be at the side of the recipient. The lunchboxes and other plastic products are also ideal for transfer printing. The advertising company also has a special opportunity to shine in the cold months, when people prefer to retire with tea and cookies. Because transfer printing is also particularly good on metal items such as thermal mugs. So there are no limits to the way in which you can best present your advertising message.

Our conclusion

Transfer printing is an ideal way of printing textiles, but also other objects. Transfer printing is particularly recommended for advertising campaigns by brick-and-mortar shops that want to use printed promotional items, such as T-shirts, to push their business. Before deciding on one or the other printing variant, you should compare all the options to save time and money. Ideally, a consultation should take place in the respective shop, because every shop has different printing options.

.png)

.png)

.png)